Harnessing the Power of Industrial Automation for Business Growth

In the modern business world, industrial automation has become an essential tool for companies looking to increase efficiency, reduce costs, and improve overall productivity. This technology allows businesses to automate various tasks, processes, and operations that were previously performed manually by employees.

What is Industrial Automation?

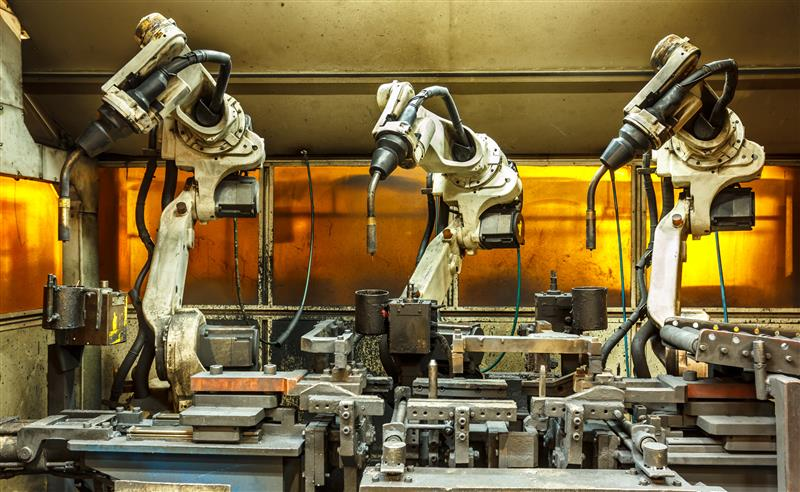

Industrial automation refers to the use of control systems such as robots, computers, and information technologies to handle different processes and machinery in an industry. These systems can be programmed to function automatically, reducing the need for human intervention. The goal of industrial automation is to streamline operations and make them more efficient by eliminating human error and increasing production speed.

Benefits of Industrial Automation

Many businesses have already embraced industrial automation and are reaping numerous benefits. Some of the advantages include:

Increased Efficiency and Productivity

By automating repetitive tasks, businesses can significantly increase their efficiency and productivity. Machines can work faster and more consistently than humans, resulting in a higher output with fewer errors.

Cost Reduction

Automation reduces the overall cost of production by eliminating the need for manual labor. Businesses can save on labor costs, training expenses, and employee benefits.

Improved Quality and Consistency

Automated systems can perform tasks with a higher level of precision and accuracy, leading to improved product quality. This consistency helps businesses maintain their standards and build a reputation for delivering high-quality products.

Enhanced Safety

Automation eliminates the need for employees to perform hazardous or repetitive tasks, reducing the risk of injuries in the workplace. This not only promotes a safer work environment but also leads to fewer lost hours due to accidents.

Flexibility and Scalability

Industrial automation allows businesses to adapt quickly to changing market demands and scale up or down production as needed. This flexibility enables companies to meet customer demands efficiently and stay competitive in the market.

Applications of Industrial Automation

Industrial automation has a wide range of applications across various industries, including manufacturing, healthcare, transportation, and agriculture. Some of the most common applications include:

Assembly Line Automation

The most well-known use of industrial automation is in assembly line production. Automated systems can perform repetitive tasks such as welding, painting, and packaging at a faster rate with greater accuracy.

Quality Control

Automated systems can inspect products for defects and inconsistencies during the production process, ensuring that only high-quality products reach the market.

Inventory Management

Automation can also be used to manage inventory levels, track items in warehouses, and replenish stock automatically. This reduces errors and eliminates the need for manual counts, saving time and increasing accuracy.

Robotic Process Automation (RPA)

RPA involves using software robots to automate routine tasks such as data entry, data processing, and customer service. This technology allows businesses to free up employees’ time for more critical tasks and improve overall efficiency.

How to Implement Industrial Automation in Your Business

Implementing industrial automation in your business requires careful planning and consideration. The following steps can help you successfully integrate automation into your operations:

1. Identify Tasks and Processes to Automate

Start by identifying tasks and processes that are time-consuming, repetitive, or prone to human error. These are the areas where automation can have the most significant impact.

2. Choose the Right Technology

Select automation technology that aligns with your business needs and goals. Consider factors such as cost, functionality, ease of use, and compatibility with your existing systems. Companies like APG provide a wide range of automation solutions that cater to different industries and business sizes.

3. Train Your Employees

Ensure that your employees understand how to use the new automated systems, and provide them with proper training to operate, maintain, and troubleshoot the technology.

4. Monitor and Evaluate Performance

Regularly monitor and evaluate the performance of your automated systems to identify any issues and make necessary adjustments. This will help ensure that the technology continues to operate smoothly and meet your business objectives.

Conclusion

In conclusion, industrial automation is a powerful tool that can revolutionize the way businesses operate. By implementing automation, companies can increase efficiency, reduce costs, improve product quality, and stay competitive in today’s fast-paced market. However, it is essential to carefully plan and choose the right technology for your specific business needs to reap these benefits successfully. With the right approach, industrial automation can help your business thrive and achieve its full potential. So, if you haven’t already, consider implementing automation in your company and experience the positive impact it can have on your operations